easyJet and Rolls-Royce unveil a key milestone in their research project, finding that an engine running on 100% hydrogen can be combusted at conditions that represent maximum take-off thrust.

Last year, Rolls-Royce and easyJet announced a partnership to research hydrogen as an alternative to fossil fuel powered flights as part of their commitment to net zero emissions.

easyJet CEO Johan Lundgren said hydrogen is “the future of short-haul aviation” and the success of the test demonstrates its “becoming ever closer.”

“We remain optimistic that it will play a critical role in helping us achieve the ambitious goals we set out in our net zero roadmap,” he added.

Rolls-Royce chief technology officer Grazia Vittadini said: “This is an incredible achievement in a short space of time. Controlling the combustion process is one of the key technology challenges the industry faces in making hydrogen a real aviation fuel of the future.”

Subscribe to Sustainability Beat for free

Sign up here to get the latest sustainability news sent straight to your inbox everyday

Behind the technicalities of the hydrogen breakthrough

The companies have been working with Loughborough University and the German Aerospace Centre Deutsches Zentrum für Luft-und Raumfahrt (DLR)

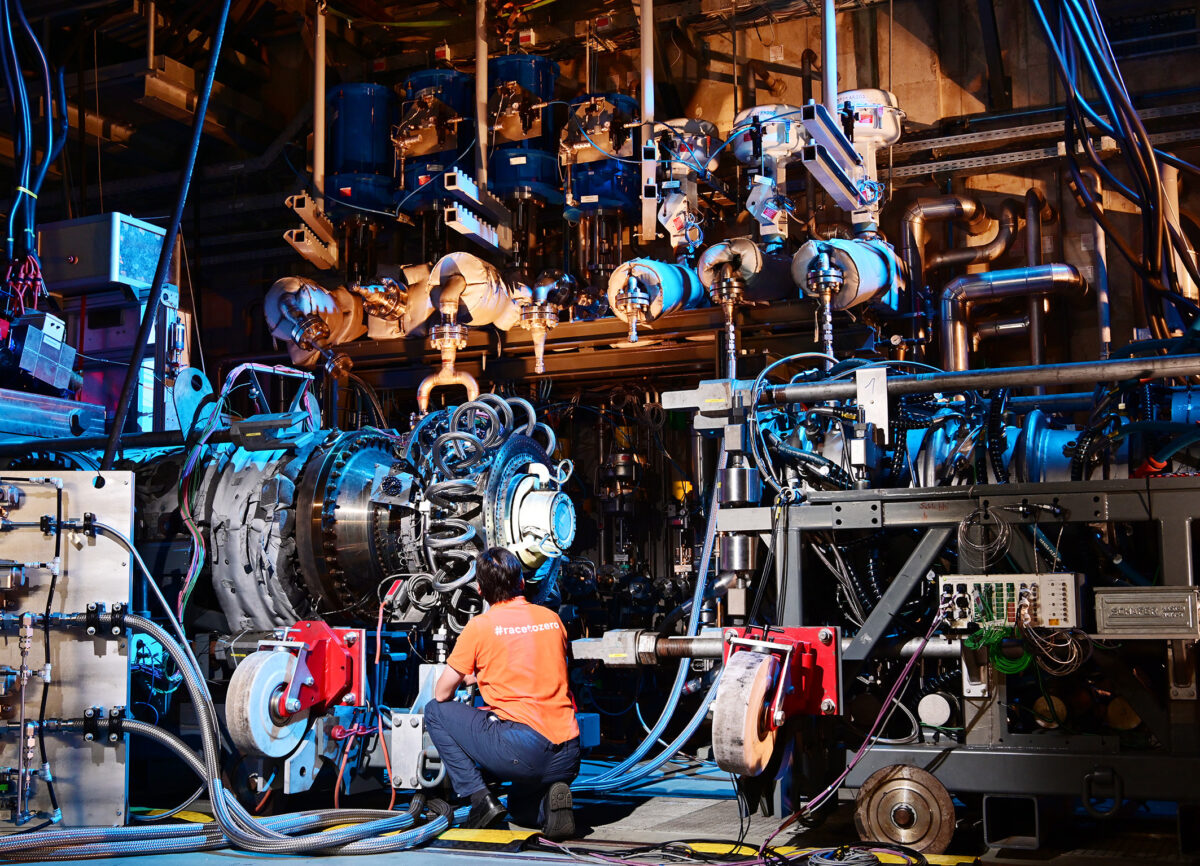

Tests on a full annular combustor of a Pearl 700 engine at DLR in Cologne found that running on 100% hydrogen have proven the fuel can be combusted at conditions that represent maximum take-off thrust.

Key to that achievement has been the successful design of advanced fuel spray nozzles to control the combustion process.

This involved overcoming significant engineering challenges as hydrogen burns far hotter and more rapidly than kerosene.

The new nozzles were able to control the flame position using a new system that progressively mixes air with the hydrogen to manage the fuel’s reactivity.

The researchers to confirm that combustor operability and emissions were both in line with expectations.

The individual nozzles were initially tested at intermediate pressure at Loughborough’s recently upgraded test facilities and at DLR Cologne before the final full-pressure combustor tests took place at DLR Cologne.

These recent tests mean the combustion element of the programme is now well understood, while work continues systems to deliver the fuel to the engine and integrate those systems with an engine.